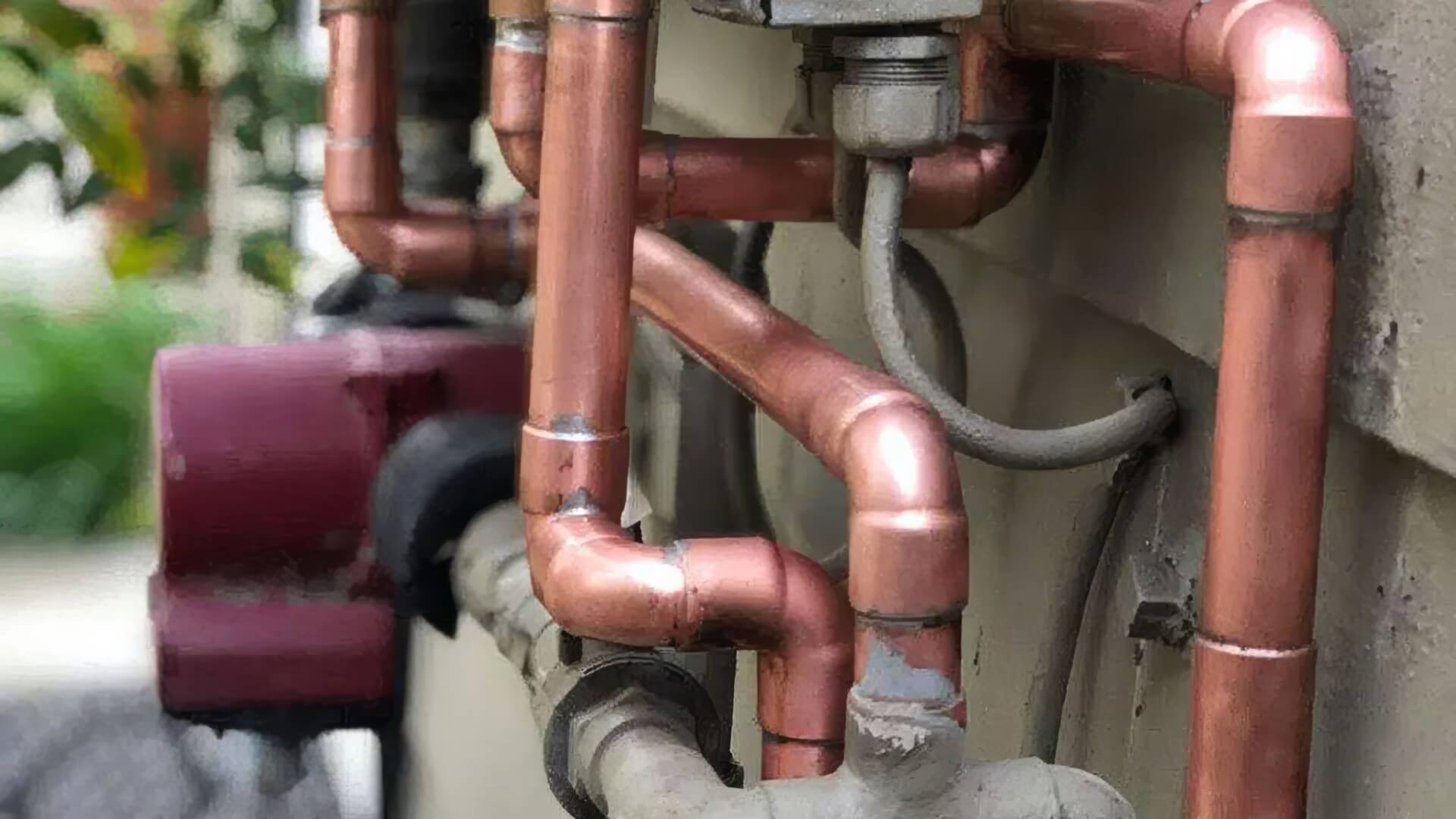

Understanding Pipe Relining and How it Works

Drain relining efficiently repairs damaged pipes without excavation, by inserting an epoxy resin liner into the existing pipe and curing it to create a new pipe within the old one.

Pipe relining offers significant advantages, including:

- Less disruptive - Relining repairs issues without digging up floors, driveways, or gardens.

- Cost-effective - Relining reduces labour and restoration costs.

- Durable - The relined pipe becomes more robust than when it was new.

- Versatile - Suitable for bends, junctions, and hard-to-reach areas.

The pipe lining process involves:

- A CCTV drain camera inspection to assess damage

- High pressure water jetting to clean pipe interior

- Resin liner inserted through access points and inflated

- Liner cured using a hot water system or UV light to harden.

- End connections reinstated

I would highly recommend pipe relining for it enables your plumber to repair your pipes without interrupting your business operations, providing an ideal solution to maintain productivity while fixing essential plumbing infrastructure.

The Benefits of Trenchless Pipe Relining for Businesses

Pipe relining presents many benefits, significantly reducing potential disruptions to Sydney businesses during essential plumbing repairs or maintenance:

Minimal Disruption

Pipe relining enables us to repair sewer pipe issues with minimal impact on corporate activities, as it requires no excavation. It is accessed through small entry points, negating the need to dig up floors, walls, driveways, or landscaped areas. We always ensure that our innovative pipe relining technology results in marginal disruption to productivity and foot traffic.

Cost Savings

Eliminating excavation, pipe relining lowers labour requirements and diminishes restoration costs compared to traditional pipe replacement. This durable technology safeguards against blocked sewers, delivering financial savings in the short and long term.

Enhanced Flow & Durability

The cured-in-place lining resolves inner plumbing pipe damage while providing a smooth protective barrier inside old pipe that prevents tree roots infiltration and improves flow rates. The restored pipe is structurally reinforced to be more durable than the original.

Choose our trenchless pipe relining in Drummoyne to effectively address severe pipe damage with preventative maintenance, ensuring urgent repairs are carried out with limited impact on business operations. Contact our team at Drummoyne Plumbing for a free quote today.

Minimal Disruption During Pipe Relining Projects

With small access points instead of digging trenches, our Sydney relining expertise allows us to swiftly tackle plumbing problems with pipe repairs inside commercial premises including:

- Warehouses

- Factories

- Restaurants

- Shopping centres

- Hotels

In most scenarios, staff and customer movements remain largely unaffected, helping to keep your utilities like electricity and water connected. This approach mitigates costly downtime and ensures that plumbing operations proceed without interruption.

Our skilled team precisely documents necessary repairs using CCTV drain cameras, ensuring effective solutions. Our technicians quietly and meticulously perform plumbing repairs by inflating resin liners and reinstating connections post-curing for an unobstructed drain.

Connect with Drummoyne Plumbing to see how our Bondi pipe relining services can resolve issues with minimal disturbance. We provide obligation-free quotes, financing options, and offer 24/7 emergency repairs.

Maintaining Business Continuity

Drummoyne Plumbing ensures minimal disruption during pipe relining projects, encouraging repeat business thanks to our careful process. Our dedicated teams meticulously plan each job to ensure the best outcomes for your commercial requirements.

For most commercial relining jobs, our customers can expect us to complete the work with limited impact on their business. Key steps we take to minimise disturbances include:

- Arranging access during quiet trading hours or after close of business

- Working section-by-section to avoid high traffic areas

- Employing dust sheets and thorough clean up strategies to ensure no mess and minimal noise

- Keeping essential utilities connected

While each situation is unique, pipe relining is typically completed in just a day or two, compared to traditional pipe replacement which can take over a week. This allows your operations to continue relatively unimpeded.

Our project coordinators will discuss with you to devise a customised strategy suiting your specific commercial requisites, ensuring we get job done efficiently. Strategically implemented, pipe relining facilitates quick remediation of damaged pipes without disrupting business activities.

What to Expect During the Pipe Relining Process

When I called them to undertake relining pipe at your business, you can count on a smooth process with few interruptions. Here is an overview of what to expect:

- Initial CCTV Drain Inspection - We thoroughly inspect the pipe condition using a small camera. This pinpoints the damage and clarifies what was the underlying issue to inform the relining strategy.

- Pipe Preparation - We use high-pressure water jets to clean the pipe interior so liners can adhere correctly.

- Resin Lining Insertion - We insert flexible epoxy resin liners through access points like manholes. An inflatable bladder expands the liner to fit.

- Curing & Hardening - We use hot water or UV light to cure the resin liner. As it hardens, it forms a smooth, protective inner barrier.

- Reinstating Connections - Once cured, we reopen service connections and lateral junctions using remote-controlled equipment.

- Final CCTV Inspection - Our camera surveys the relined pipe to make sure our quality work meets rigorous standards.

Throughout the swift 1-2 day relining process, we operate discreetly to safeguard your drains from disruptions. Once we came out to perform our services, your operations could continue with relatively unimpeded functionality.

Choosing a Qualified Pipe Relining Company

Select a professional pipe relining company with proven expertise for your Sydney business through thorough research.

We recommend asking potential contractors key questions about their experience, such as:

- How long have you offered plumbing services such as pipe relining?

- How many commercial relining projects do you handle annually?

- Can you provide references from past business clients?

- Are your technicians fully certified and insured?

Drummoyne Plumbing, known for its exemplary services and reliability, is the experienced firm you need. With 10+ years specialising in pipe relining across Sydney, our skilled teams have repaired thousands of damaged pipes at schools, hospitals, factories, restaurants and more.

Our company maintains all required state licenses, industry accreditations, and liability insurance. Our technicians deliver professional services, integrating advanced technology and safety-focused practices for dependable outcomes in every commercial project.

For cost-free quotes or advice, our local Drummoyne experts will guide you in selecting the best pipe relining company for your business’s needs – email us or call 1300 349 338 today.

The Strength and Durability of Relined Pipes

Pipe relining can dramatically enhance the strength and durability of damaged pipes. Epoxy resin liners can also form a robust barrier that is scientifically engineered to outlast traditional pipe materials.

Our high-density polyethylene (HDPE) and polyurethane resin liners have a 50+ year design life. They are also markedly stronger than traditional cast iron and PVC pipe materials, as verified by physical testing.

The thermoset plastic chemistry endows the liners with exceptional tensile strength. The hardened plastics will not melt or soften, ensuring lasting durability. The resin’s dense cross-linked structure resists corrosion, abrasion, chemicals and tree root intrusion.

Our use of advanced CIPP (cured-in-place pipe) technology allows for the installation of seamless custom-fit liners, ideal for storm water pipes. Our exacting robotic tools distribute heat or UV light evenly for curing the resin, ideal for your water and sewer storm water pipes. This results in a smooth, joint-free lining that perfectly moulds to the shape of your pipe.

The relined sewer line, serviced with meticulous attention, can get repaired inside the old pipe with no joints or welds to weaken over time. Our non-invasive approaches prevent damage your pipe collapse while ensuring a reinforced, enduring integrity to your plumbing systems.

Contact our team about our relining service to strengthen your plumbing infrastructure for the next 50+ years.

Returning to Normal Operations

Following the relining procedure, drains are restored, enabling a swift return to regular operations. The discreet nature of our work means daily activities are unlikely to be impeded during relining, even in the presence of blocked drains.

After reinstating connections, we conduct final quality testing using CCTV drain cameras. This ensures that your refurbished pipes meet strict standards and are returned to optimal condition without excavation or extended downtime.

Relined pipes deliver enhanced flow efficiency, longevity, and resilience against blockages, providing peace of mind and a solid foundation for future plumbing requirements. This offers consistent security for your plumbing infrastructure and peace mind for our valued customers.

Our non-invasive techniques ensure quick maintenance with little effect on productivity. And with tougher, 50-year rated pipes, you can expect less disruption from future repairs.

To learn more about maintaining business continuity with pipe relining in Sydney, email us or call 1300 349 338. Our team is always ready to answer your questions and provide obligation-free quotes.